Hey hey hey!

This greeting always reminds me of that bitconnect event. If you don’t know what it is, you have to check out this clip on YouTube.

This one is going to be interesting to you (hopefully), I promise!

Let’s rewind back to December last year, I was planning to make some huge batches of zinstax and binstax during the Christmas Holiday so I can finally concentrate on my master thesis.

However, I soon realized I was short on parts, parts of the crank assembly, to be precise. Great supply chain management, Han! In my defense, I’ve always had the impression that I’ve got enough parts because I ordered so many of them last time that I totally lost count. Plus, binstax has been selling like hotcakes, so I ran out of parts before I even realized.

I mentioned in the last post that I had the genius idea to integrate the crank assembly into a single piece, so I can skip a step while putting it together. And it’s probably stronger, too. I also admitted that this turned out to be a stupid idea because no one was willing to manufacture an weird looking part with some funky geometries. “I’m not paid enough for this shit” is perhaps an accurate portrayal of the worker as soon as he saw my order.

If you’re surprised that I don’t have a local manufacturer as a partner, I’ve been ordering parts on Hubs since the beginning of the zinstax project and I’m satisfied with the quality. So I just kept ordering parts from them. They have a global network of manufacturers, and all of my CNC parts seemed to be made in some factories in China. I know “made in China” is almost always frowned upon, but Hubs‘ Chinese parters are the real deal. You get parts within a ±0.01mm tolerance for the price of ±0.1mm. And the surface finish is *chef’s kiss*.

So I shot them an email right away and a guy called Las replied with lightning speed. Basically he told me it was inevitable that the delivery date is pushed back because all their Chinese partners are closed for the Chinese New Year.

He was also curious enough to ask who am I and what these parts are for? I replied with a few links to this site. We made a phone call later and chatted a little bit on WhatsApp. He was super impressed with zinstax/binstax. We then met up in Bonn a few days later, I brought all of my stuff with me, of course. He told me at the Café that he’s always been wondering why I, using a private gmail address, keep ordering a ton of the same part each time and having them shipped to a private address. I lol’d so hard, I totally didn’t expect to stand out so much.

Fast forward to the beginning of February, the parts have arrived. Be ready for a dumpster fire.

I randomly picked three pieces out of, maybe 10, and saw three completely different chamfers. Also notice the one on the right, they obviously chamfered that poor little thing free-hand. How could this have passed their quality control?

Not to mention the chamfers are not even consistent across all parts.

The surface finish is horrendous. And again, three different chamfer sizes. I can’t, in all conscience, ship your zinstax/binstax with these and pretend it’s fine.

They also reduced the depth of the arrow from 0.5mm to 0.3mm without my knowledge. I wanted to highlight the arrow with a color dye. I absolutely needed that depth so the liquid dye won’t climb out before it’s cured.

I was literally speechless and didn’t know what to do. I dropped Las a message, and he said this was not acceptable, I should file a dispute, which I then did.

I decided to visit Las in their headquarters in Amsterdam.

I had to travel to a small town in the Netherlands called “Heerlen” by bus and take a two-and-a-half-hour train ride from there directly to Amsterdam. I missed the bus by literally a second. The bus driver was kind enough to not let me get on, so I waited a half hour for the next one.

If you live in the Netherlands, what’s going on with these windows? Why are they so dirty? I struggled to take a picture out of it because my phone kept focusing on the schmutz 😂

Their headquarters is literally on a harbor.

Must be amazing working here!

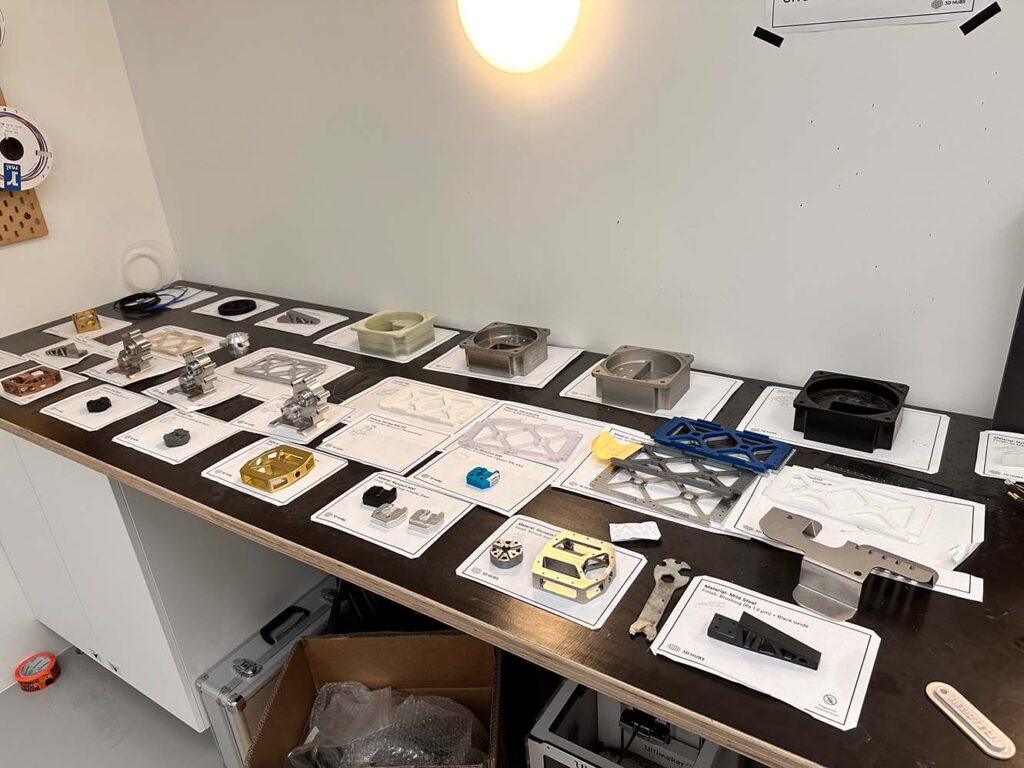

They even have a dedicated workshop with a couple of 3D printers, you can print your stuff here for free all day long, if you work here.

These are some sample workpieces with various materials and surface finishes.

Close-ups.

I also did an interview with them while I was there. Well, they told me beforehand that they wanted to interview me because my product is well suited for their marketing. They have yet to meet anyone who has used almost all of their services (CNC machining, Sheet metal, 3D printing and injection molding), and on top of that, made a presentable product out of it.

However, I didn’t know they were going to make a short video too, so I came totally unprepared. I thought I did great but when they sent me the video for preview, I couldn’t watch it for even two seconds because I sound like I haven’t hit puberty at all. And I look totally unenthusiastic and lifeless, although truth be told, I have been staying up pretty late. I told the videographer to just publish it because all my friends said it looks very professional and it’s too painful for me to watch. Maybe I’m too self conscious, but I really don’t like how I look and how I sound.

Las and I went to a burger shop he frequented for dinner. I saw they have Wagyu beef burger which I’ve never tried before so I went with that. It was good, probably the juiciest burger I’ve ever had, but my god look at the price. Las paid for me, “because you’re the guest”, I’d just get a normal burger if I knew you were going to pay.

Amsterdam is soooo beautiful, especially in the night.

Fun fact, news came out the day after I came back that Amsterdam is going to ban people from smoking weed on the streets. Is this personal?

In the end, Hubs decided to scrap the parts that were an eyesore and refund me in full.

I went ahead and placed another order for a thousand pieces. Now what’s left is, you guessed it, wait.

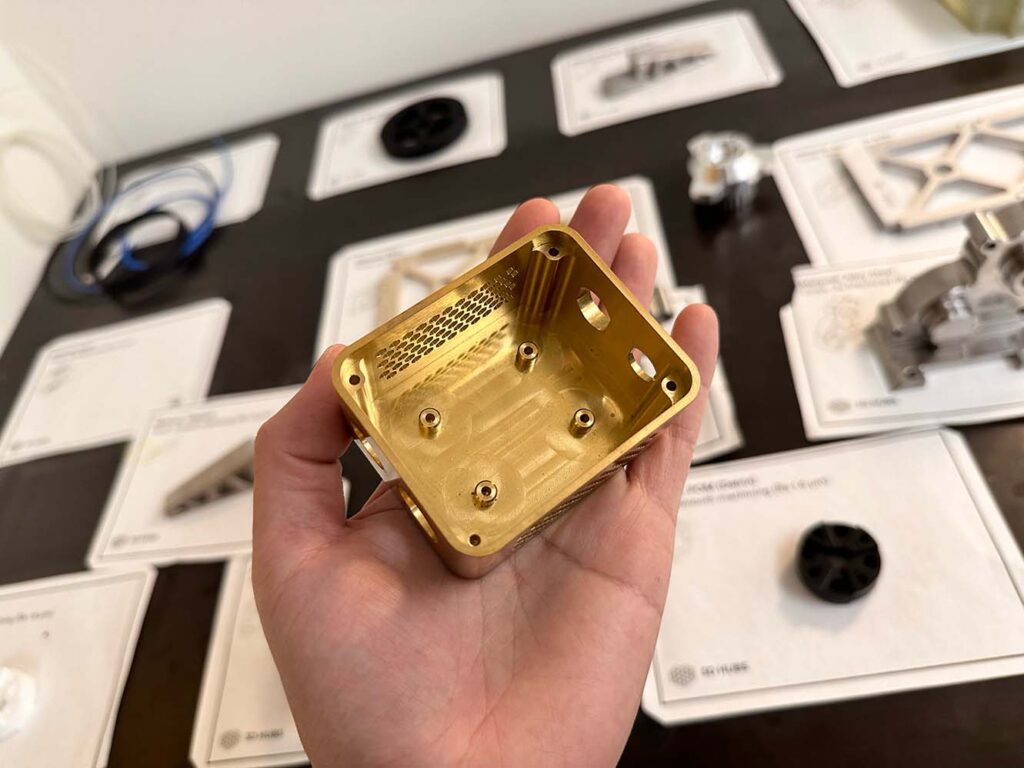

In the meantime, these binstax studs came in. Nothing special, I thought I’d show you how shinny and gold-like they are. I was in the middle of washing them in an ultrasonic bath with isopropyl alcohol and I just couldn’t stop appreciating their beauty.

A few days later, at around the end of February, this part arrived as well. This has an odd left-handed thread in an odd size (M2.3). 7000 series Aluminium anodized jet black. It’s clearly not made by the same manufacturer from last time, don’t ask me how I know.

They even added this minuscule chamfer which I didn’t ask for.

I can’t get enough SQ1 quickly enough, and these are always a lot of fun to unbox, yay!

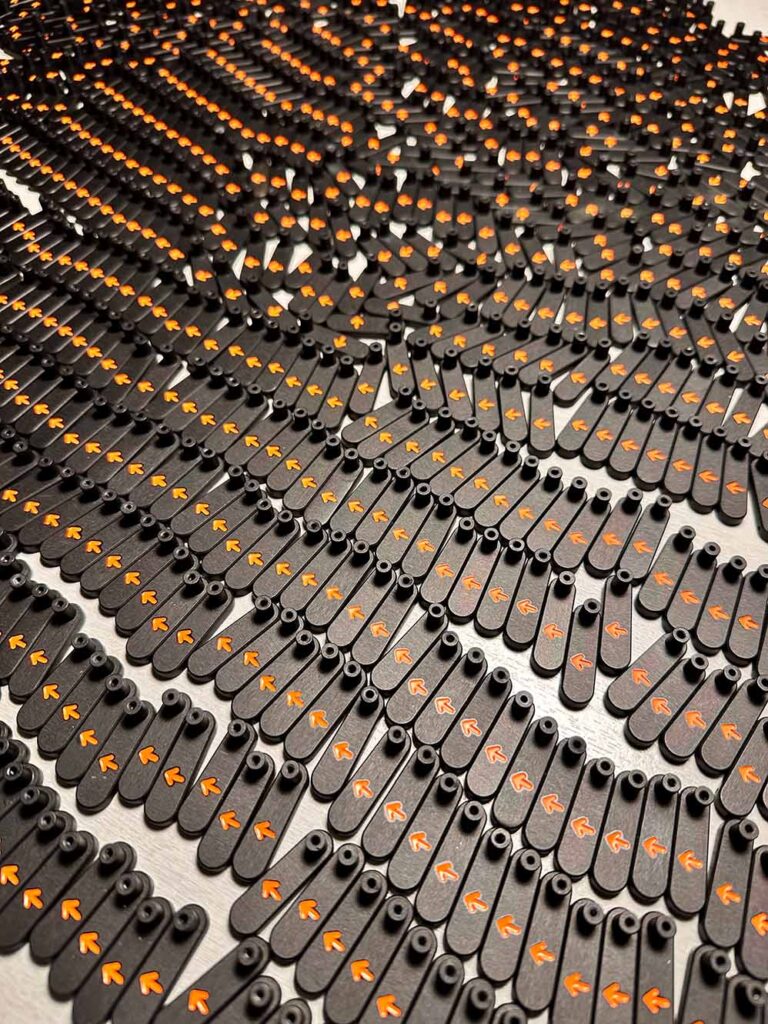

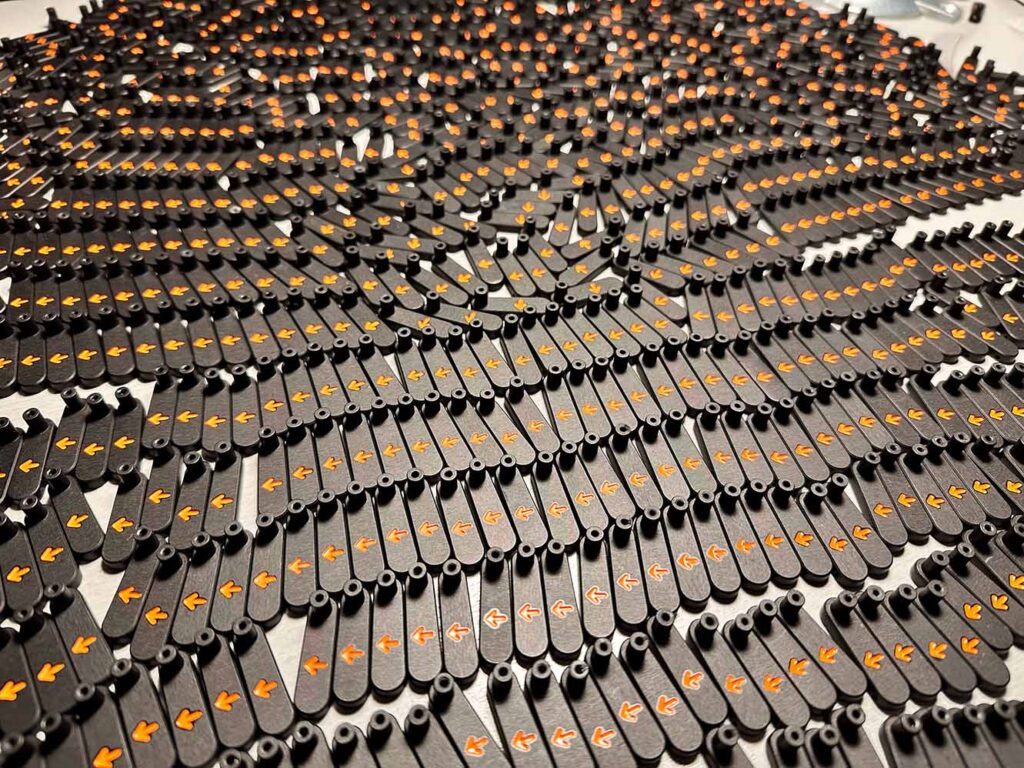

I kept waiting, and it’s already April. These finally came in. It didn’t give me a heart attack during unboxing.

There’s one thing that bugged me a little though. These should have been bead blasted but it doesn’t look quite like the right finish to me. It’s more like a brushed finish, and you can clearly tell the difference.

But it’s not too bad though, just different. The tolerance is super tight, and more importantly, the chamfers are consistent.

I want to thank Derek for his super in-depth comment on the last post. He suggested trying out color fills by a company called Cerakote. They offer a variety of color coatings, so I picked one that looks flashy but not too ostentatious.

After tinting those arrows orange a thousand times, I almost can’t see anything clearly that’s far away. And rubbing them with acetone after the colors are cured wasn’t too pleasant either. Acetone eats nitrile gloves for breakfast, lunch and dinner, no cap.

It does look fabulous though! I’m really satisfied how they turned out.

I’m going into production these days so I might not be able to reply to your emails in time.

I’m not sure if this interests you, but I thought I might as well share.

I got into electronics lately for some unknown reasons. To be frank, I’ve always been interested in electronics, I just didn’t know where I should start. I got hooked up in Switch-Mode Power Supplies, and lasers, so I decided to make a switch mode laser diode driver.

I’m tired of green and red laser pointers you can get almost everywhere for dirt cheap, so I got myself a 488nm cyan laser diode. Originally, I wanted a 589nm golden laser, but it’s a diode pumped solid state laser which involves some fancy non-linear crystals that are way beyond my league, both price-wise and knowledge-wise.

Luckily you don’t need any crystals for a 488nm laser. Thanks, Scientists! Just shine the light through a collimator and you’re golden (cyan). I hooked it up to the bench power supply and holy shit, this thing is out of this world.

It has to be said that any focused laser beam with a power greater than 1mW is extremely dangerous. Even a reflection from a shiny object can cause permanent eye damage faster than you can blink. I will only fire up this diode with my curtains shut and doors closed so no one could ever get hurt. I wear laser safety glasses and use my phone to take pictures because I can’t see the beam through the glasses.

The safety glasses is actually pretty cool, it has a sharp cut-off wavelength at 532nm which means it filters out blue and green light completely. This is what you see after putting them on. I took this picture though the lens, it’s way cooler (actually, warmer) than any filters I’ve used. It feels surreal!

These are super expensive. And look pretty rad too. But I’d rather spend some money on a pair of quality safety glasses than have my eyeballs accidentally incinerated. That laser beam could be the last ray of light I see for the rest of my life. It’s probably worth it though, that beam is so pretty. No not really.

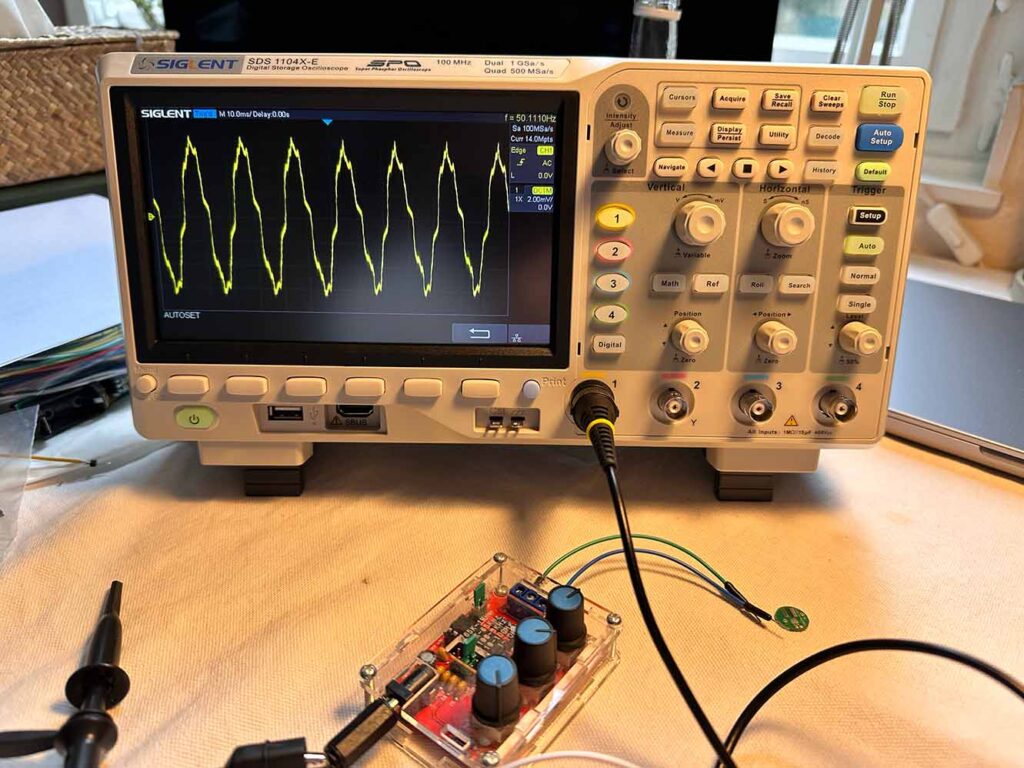

I also bought an oscilloscope. It’s awesome. You should get one too. It’s picking up 50Hz from the mains when nothing is connected. Mind blowing. No not really.

Now, a laser diode requires a constant current driver because its resistance decreases as it heats up. A constant voltage source just won’t cut it. There are plenty of off-the-shelf laser drivers but they are almost all made for stupidly powerful diodes.

I, however, am not a psychopath, and want a small and compact driver. Also where’s the fun if you just buy it? This already sounds suspiciously similar to how zinstax started.

Ah shit, here we go again.

I set out to design my own laser diode driver. Just trying to pick up some new knowledge along the way.

I tried to source a dedicated current regulator IC specifically designed for LEDs, but I didn’t have much success. I wanted to drive the diode with a single cell of CR2 battery because I have tons of them lying around. You guessed it, they come from the SQ1, and are absolutely a pain to get rid of.

Its voltage is 3.2V when new and drops to around 2.5V when it’s dead. The forward voltage of the cyan laser diode is 6V, so I need a boost converter that should at least supply 100mA at 6V. I didn’t find any IC that fits my requirements. It either can’t boost the voltage to 6V or the minimum operating voltage is too high. I found a lot of ICs that need a minimum input voltage of 2.7V, which is just barely higher than 2.5V. Bummer.

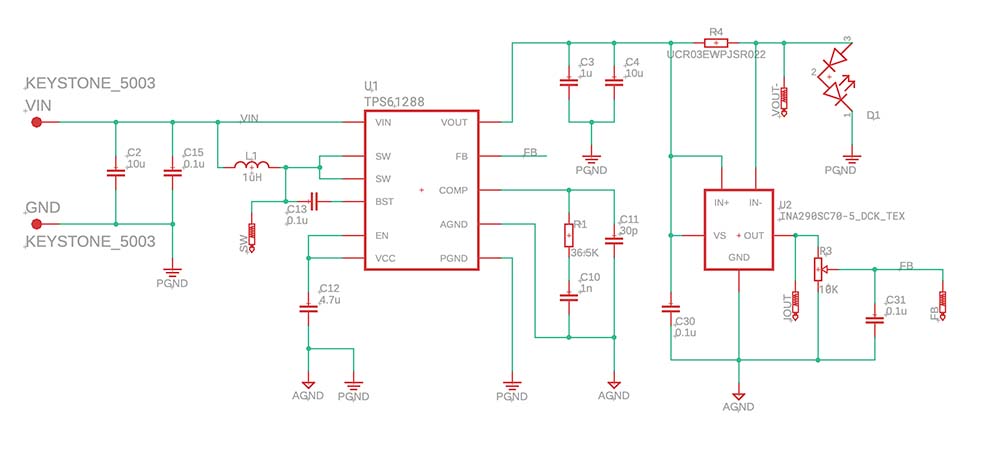

Texas Instruments has a lineup of awesome synchronous boost converters so I decided to pick one and use a current sense amplifier to trick it into behaving like a constant current regulator by monitoring the voltage drop across a small current shunt at the output and feeding it back to the IC.

I didn’t study EE so please don’t give me a hard time if my schematic looks amateur to you. In fact if you’re reading this and know better than me (you most definitely do), please drop me an email and I’d love to chat.

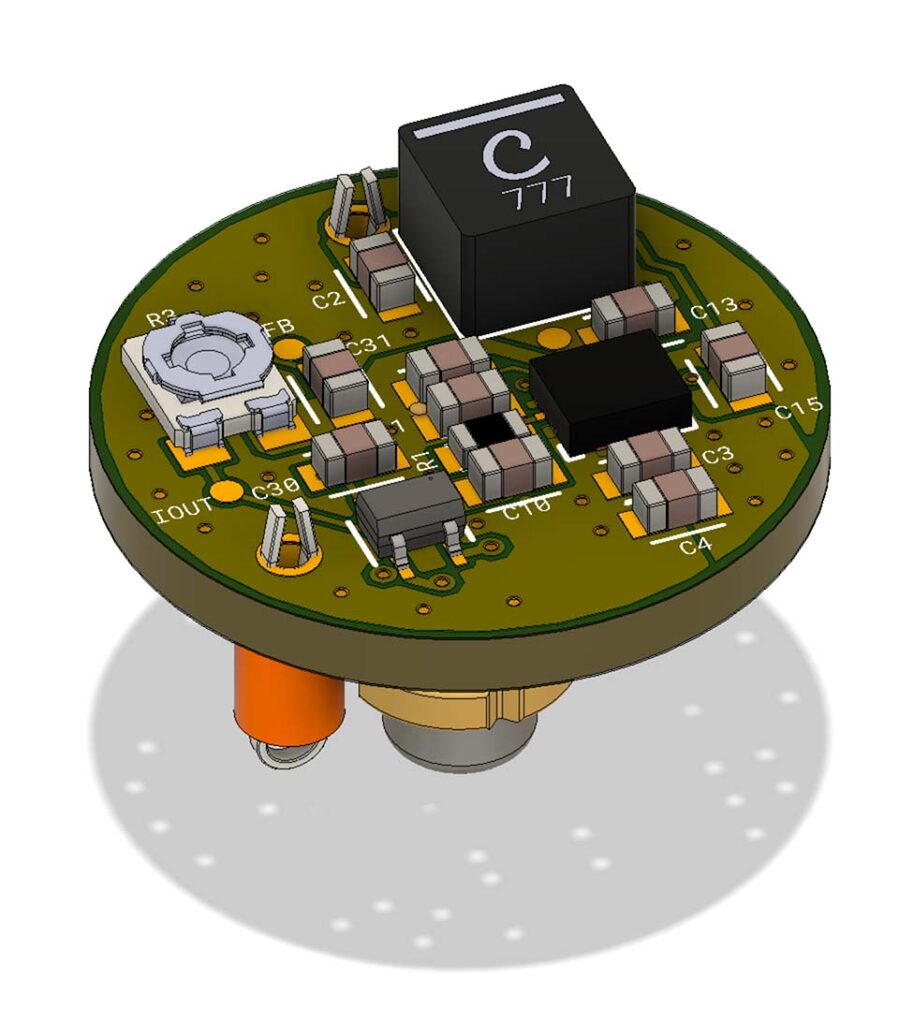

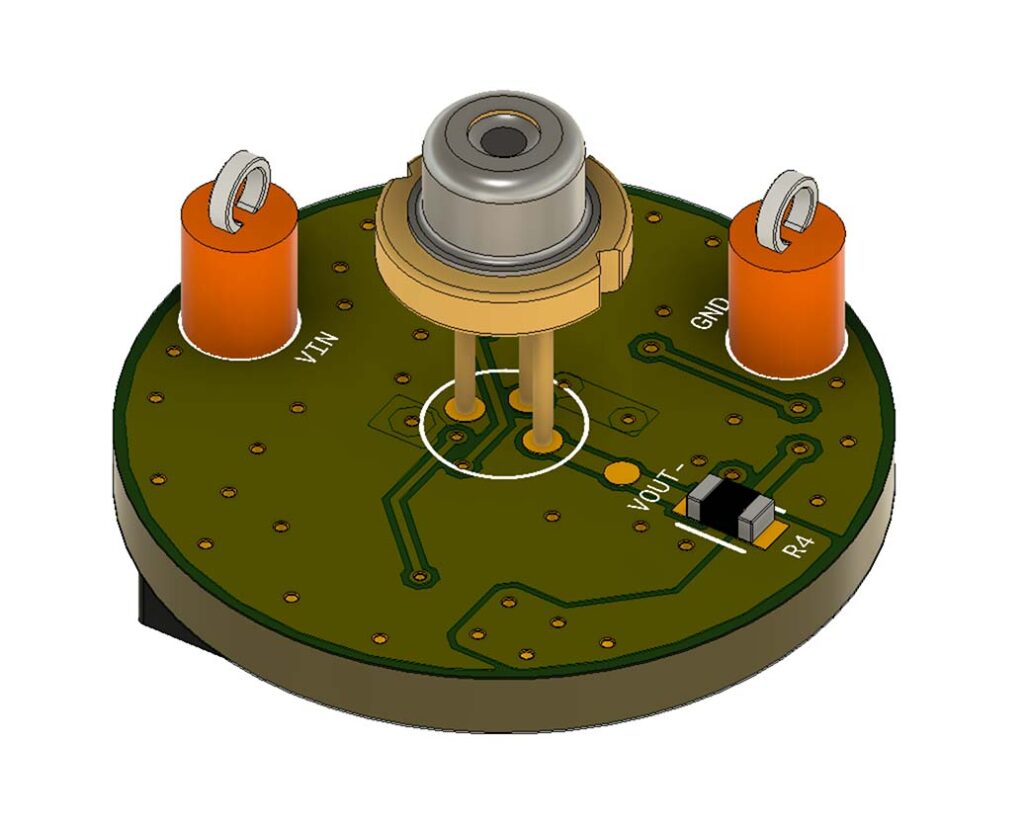

I’m using a TPS61288 as a switching regulator and an INA290 as the current monitor. I also added a potentiometer in hope of being able to finely adjust the output current and a 0.1µF capacitor to form some sort of a low pass filter to get rid of any high frequency rubbish.

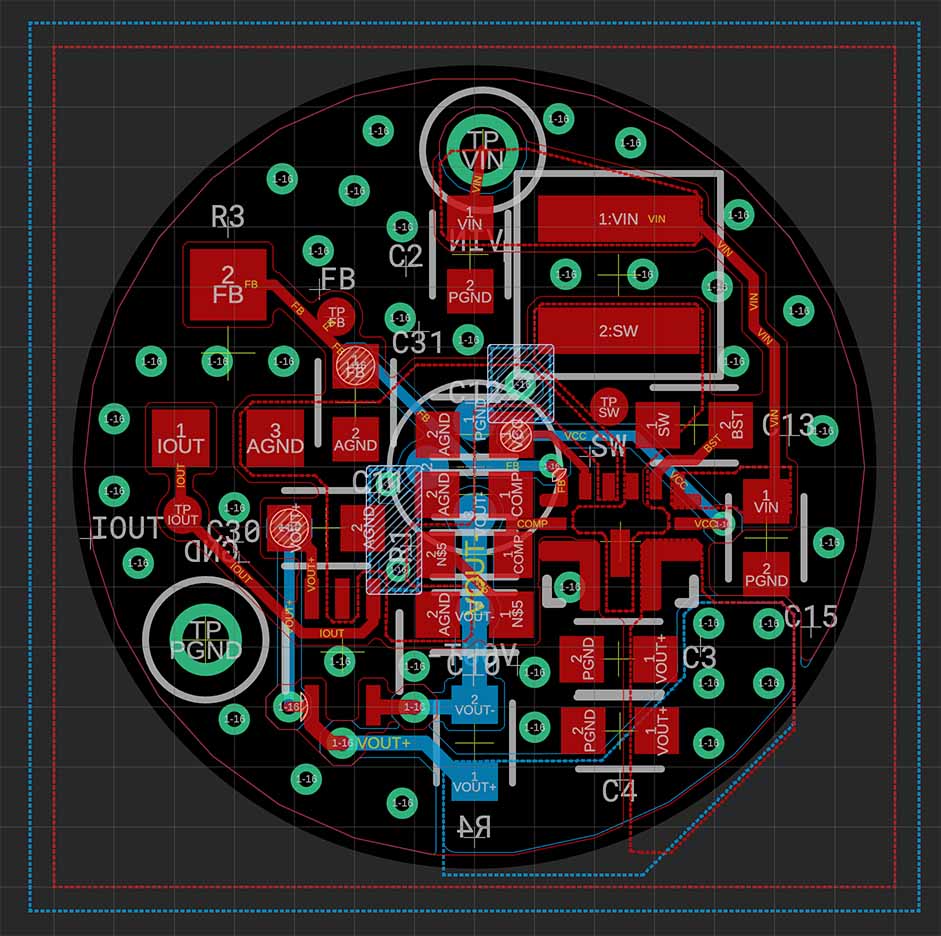

I then went on to lay out the board. Again, please don’t laugh at me for making rookie mistakes. I’d love to hear your input. I’ve read a lot about PCB design recently, it’s such a rabbit hole so I guess I’ll just go ahead and have it manufactured. It’s $2 for 5 boards anyway.

That was about it. I realized this site is slowly turning into my personal blog. Not sure if this is what you expect though, but I’m still making zinstax and binstax day and night!

Han, you are the epitome of quality over quantity! Keep up the great work and try to get some sleep good sir!!

Hey Dave, didn’t expect to see you here! I’ll make sure to post your replacement studs today!

It has been a long time since the last post. But I am happy with the update! I thought the project was suspended for eternity.

I won’t just secretly stop making these without an announcement. It was just because I ran into hiccups in manufacturing after running out of parts. Everything’s fine now so expect to hear from me soon if you’ve already signed up!

You’re one of the most important people on the planet!!! I’m so excited to get mine :))))))

Wow that’s literally the highest level of compliment I’ve ever received! Thank you so much, you just made my day!

Lets go!! Can’t wait, but I’m glad you are not taking any short cuts and are making sure the parts are the best they can be.

Haha, because I know I won’t enjoy using it if I were to receive this

Zinstax? Zinstax!! I smiled a mile wide when the email arrived and pushed that ‘pay invoice’ button right away. I’m looking forward to cranking out polaroids in the not too distant future. Thanks Han for doing what you do.

Thank you Bruce! Will let you know when your zinstax ships, have fun!

Thanks for the great works! Received your invoices yesterday, can’t wait to see the results.

Hi Eugene, thank you so much for the support!

sorry to ask, but I got the waiting list confirmation on Feb 6th, but still ahvent received my invoices, wonder if my order was skipped by accident? thanks!

I’ve just shipped a batch of binstax and will be working on zinstax next. You’ll hear back from me in June, and I’m so sorry that you have to wait for so long.

Mamiya 645 possible in the future?