Machined and anodized 7000 series Alumin(i)um. They’re the strongest Alumin(i)um alloys and are indeed “Aerospace Grade”, if you’re not tired of that kind of marketing crap.

Story time —

I’ve been developing a new mechanism to prevent the crank from being turned the wrong way (it’ll break and ruin your day) after getting slammed by a customer who was, in his own words, “too excited and broke it” by doing exactly what I warned him not to do.

He then reached out for help and I said a set of replacement gears goes for 10€. I forgot to mention shipping was 13€ and on top of that, 19% VAT because he’s in the EU.

To my surprise, he seemed to get really, really mad after receiving an invoice which was around 27€ instead of 10€, the sum he was anticipating. He then went on to accuse me of ripping him off, selling an inferior product, and stated that he would’ve said no if he knew it was going to cost 27€.

To be fair though, he’s got a good point. A great product shouldn’t break too easily. And if you’re reading this, my apologies again for not making it clear that shipping is not free.

It actually never crossed my mind to add a mechanism to allow the crank to only turn in one direction. It’s all muscle memory for me so I’ll never get it wrong, and there were only a few cases so I thought it was not a problem.

If you break it, I’d either send you a pair of replacement gears for the price I purchased them plus shipping, offer repair service if you’re reluctant to open it up by sending you a return shipping label, or another one if you need your zinstax in a hurry for a shoot and I happen to have a spare laying around. I don’t charge crazy price for my repair work, it’s free, and it has always been free since I started selling them because I really appreciate you being my customer. You’ll still have to pay for the parts, however, which are 10€, and shipping, but I think it’s fair because you’ve been warned not to turn it the other way round.

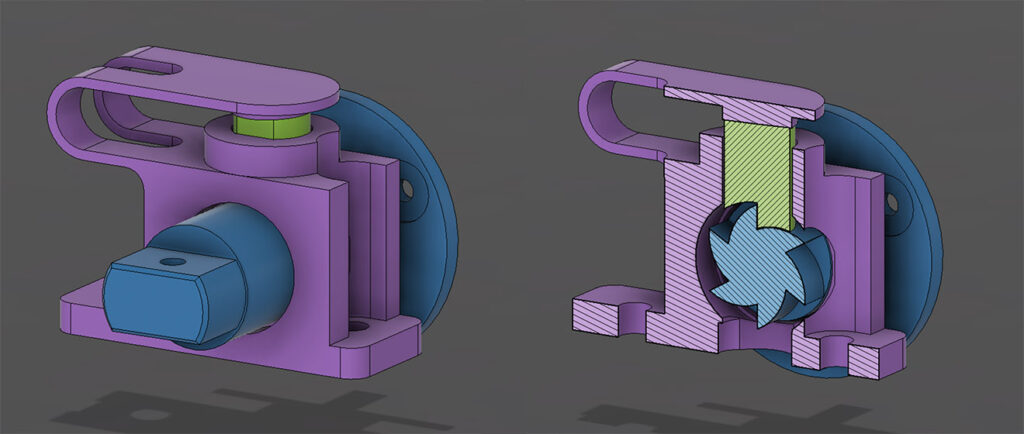

I’m keen on improving my product(s), so it’s time to come up with something to put an end to this, something like this:

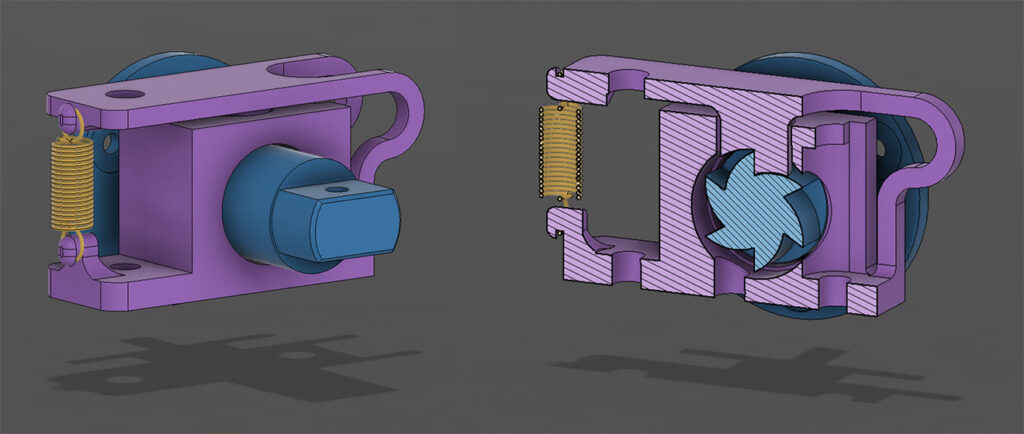

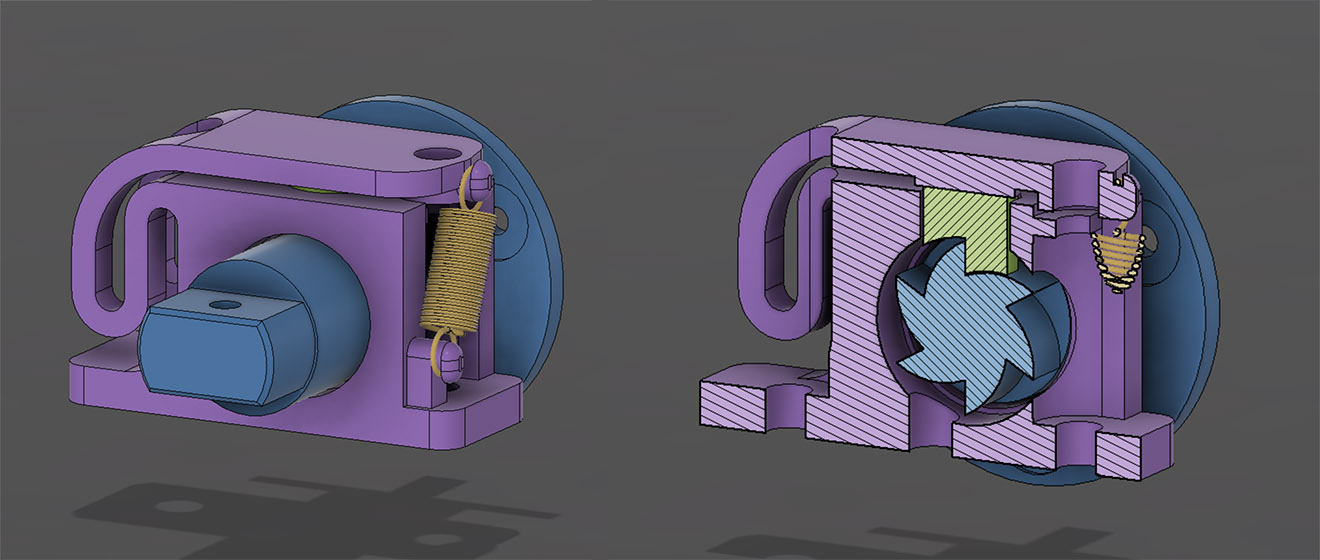

I spent days on this design which I thought was perfection:

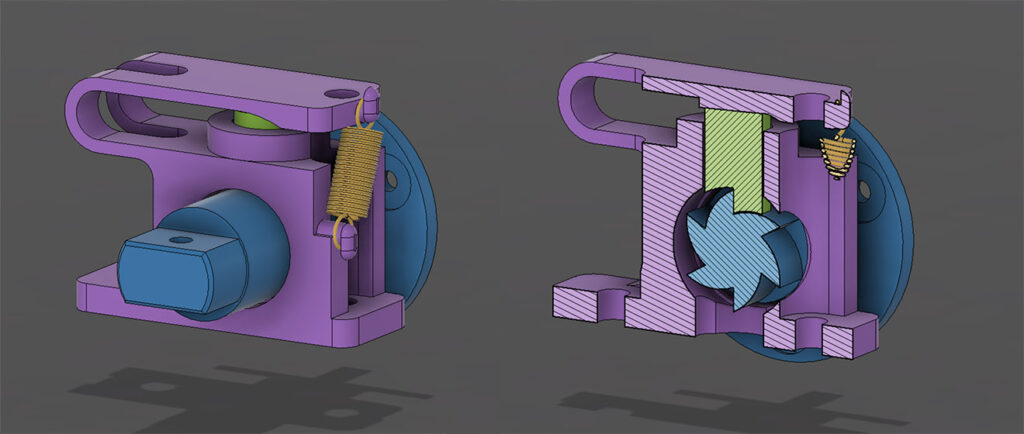

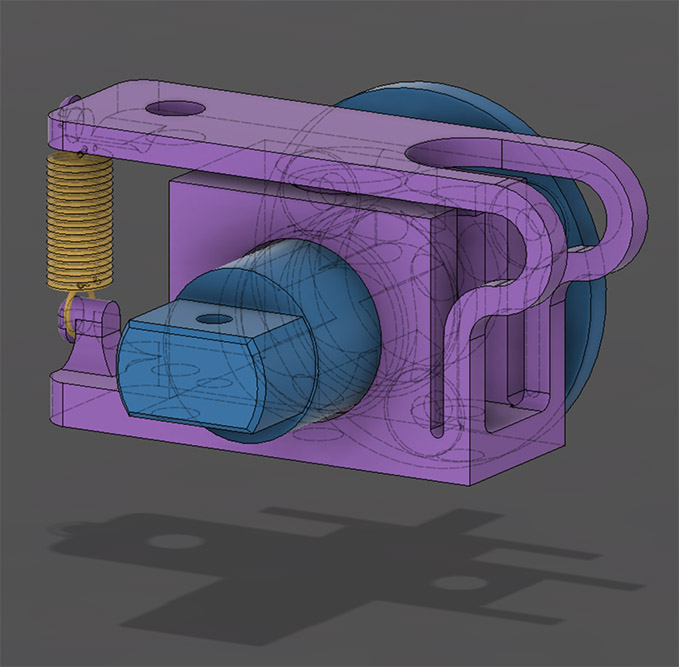

After looking at it for a few days, I was afraid the thin, bendy piece would lose tension over time, so it’s probably a good idea to add another spring on the other side. I also made it thicker, in the hope that it’ll last longer. If it’s too thin, it’ll just snap when you’re digging it out of the powder bed. The spring is oriented that way because there’s no space for it, it has to make way for the screw.

It was 3AM when I was finished with the second version, and I was pretty happy about it to say at least. Then I realized there’s not enough head room because the pin will push the bendy piece up, I didn’t take that into consideration. I had to make it more compact.

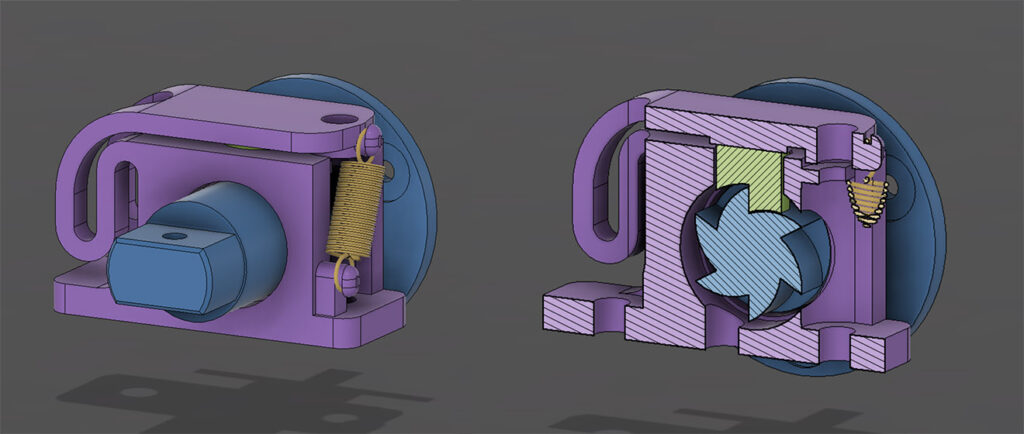

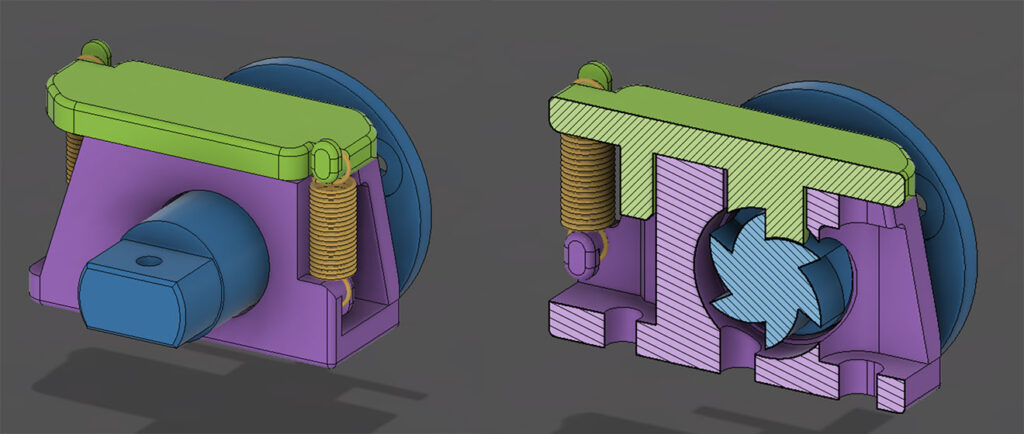

We’re now at the third version and it was 6AM or 7AM, I’m not sure. Sometimes you just can’t stop when you’re so caught up in something. I tried to make the bendy piece as long as possible to minimize the stress. Looks wicked!

Isn’t this thing a beauty? I was pretty complacent about the whole thing until it I dawned on me that the spring is constantly pulling the bendy piece sideways, which is clearly not ideal. It would be okay if the pin (green) is connected to the bendy piece so it won’t be dragged to the side because it’s stuck in the hole, but I want the pin to slide straight up and down instead of swiveling. How could I have missed this?

After some time of thorough contemplation (the birds are chirping again) I decided it would be better if the spring is moved to the other side.

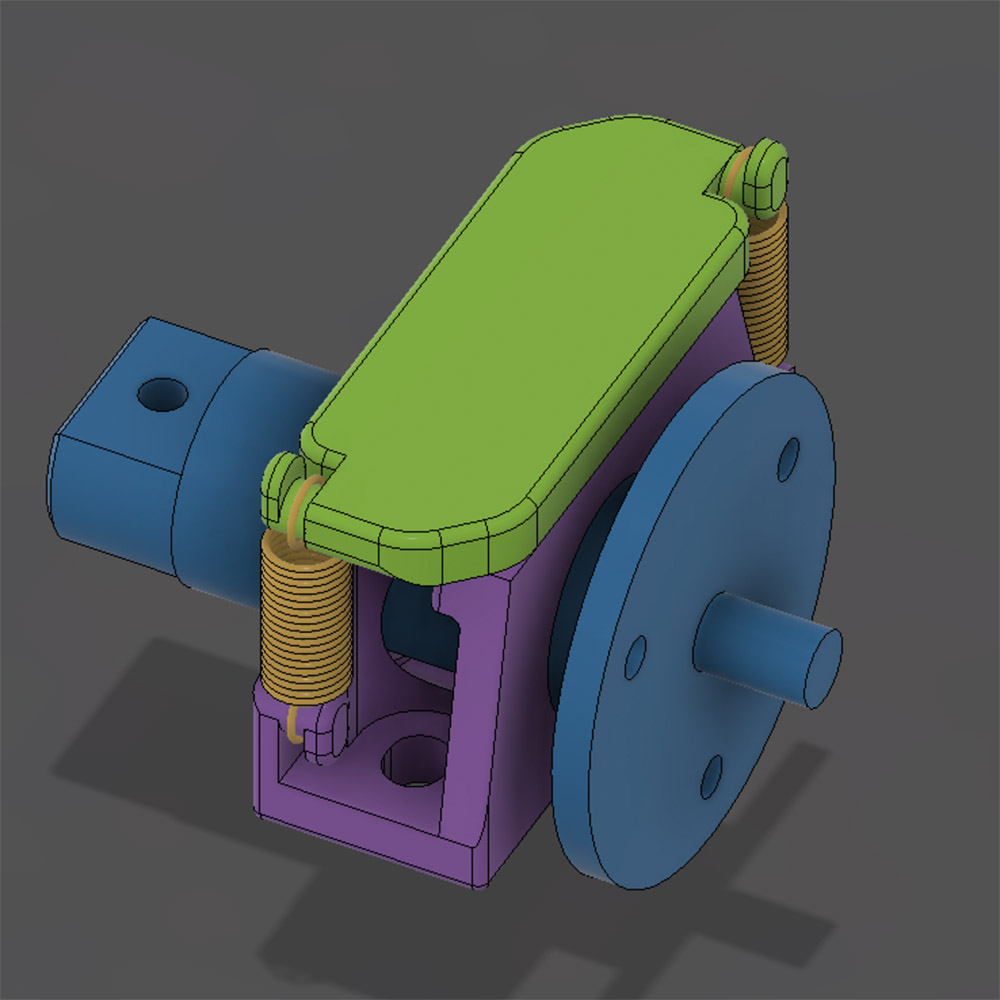

It’s half past 10 in the morning and I can finally rest.

It’s designed for the zinstax based on the white SQ1, so if your zinstax didn’t come with this feature and you really want to have it, I can send the parts to you, so you can install it by yourself, I’ll probably also write an instruction for it. For my OG customers who own a black zinstax, I’ll come up with something for it, too, thank you so much for your support in the early days!

UPDATE: I did eventually change the design significantly, again, because I don’t trust the longevity of that long and thin bendy piece made of plastic. The solution is to use two springs instead of one. They’re arranged diagonally to make room for the screws.

Great design!

Just ordered one.

Can’t wait for it!!!

To me it’s so fascinating that you are creating and improving a useable product. Just on your own. Blows my mind… Can’t wait to try mine out!